What is Wire insulation?

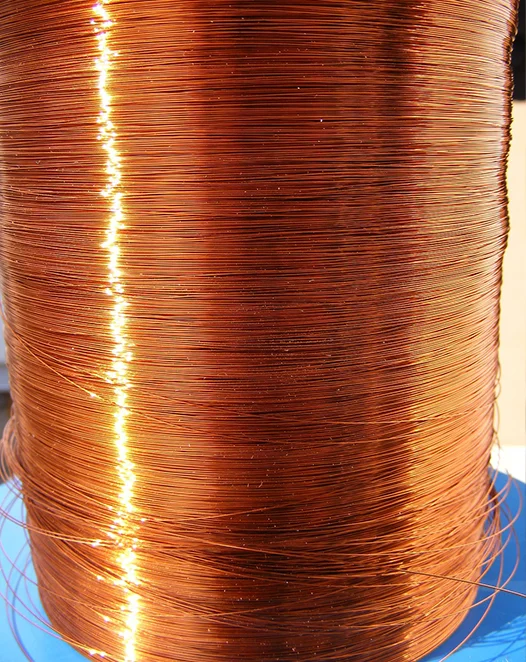

Wire insulation is a protective coating applied to electrical wires. It prevents electric current from leaking and protects against electrical shocks and short circuits. Its purpose is to ensure safety, prevent equipment damage, and maintain the reliability of electrical systems.

Wire insulation is incredibly important in electrical systems because it keeps us safe and prevents potential dangers. It acts as a protective layer around the wires, shielding us from the risk of electric shocks. Without insulation, there would be a high chance of accidental contact with live wires, which could result in severe injuries or even fatalities. Additionally, wire insulation helps to prevent short circuits, which can cause fires and damage to electrical equipment. It also provides a defense against environmental factors like moisture, heat, and chemicals that could otherwise compromise the performance and safety of the electrical system.